Food-grade silicone tube has excellent safety performance, meet the food-grade requirements can be normal contact with the human body, after adding the color gel silicone will carry out the overall discoloration, even if the change in color is also able to meet the food-grade requirements, for example, silicone straw is a variety of colors but it still meets the food-grade requirements.

Food-grade silicone tube color can be a variety of colors, including red, black, blue, green, gray, etc. Whether from the production process or out of the manufacturing process can be customized, but the color customization is required to customize the color glue. Color rubber is the most important point affecting the color of food-grade silicone tube, different colors of color rubber manufactured food-grade silicone tube color is different. The product is mainly based on the conventional seven colors while supporting custom two colors that is two-color, in addition to the color rubber can affect the color of silicone products in addition to other processes can affect.

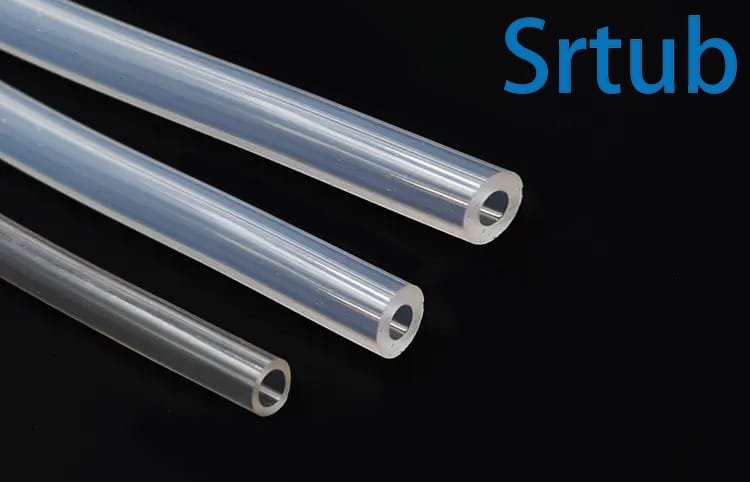

In the customer to determine the color of the main body of the food-grade silicone tube, it is necessary to practice glue to add color glue dyeing. (Special note: the majority of silicone raw material color is white or translucent or iron red rarely see other colors) in the addition of custom color glue when the portion is also very important part, if you add too much or too little will lead to discoloration.

peristaltic pump silicone tubing

Platinum vulcanized silicone tube and double two four vulcanized silicone tube judgment method

Platinum vulcanized silicone tube is added in the process of practicing rubber platinum vulcanizing agent so it is called platinum silicone tube, and double two four vulcanized silicone tube is added in the silicone double two four vulcanizing agent production. Between the two need to pass the performance, application areas, test to judge, there is a relatively simple method of judgment is the combustion method, I will analyze for you.

First need to know the general understanding of platinum vulcanizing agent, it is a two-component molding vulcanizing agent, characterized by (good environmental performance, fast vulcanization speed, the product is odorless)

Therefore, the platinum vulcanizing silicone tube in the product also has these characteristics and can be high temperature secondary curing is what we call the second plus sulfur, the vast majority of these products are used in the food and medical aspects.

WhatsApp/Wechat: +86 13075286997

Email: sales@srtub.com