Nel processo di produzione dei prodotti in gomma siliconica, a volte è necessario identificare le materie prime della gomma siliconica, quindi quali sono i metodi comunemente usati per identificare la gomma siliconica? Di seguito, Srtub Silicone Products Factory condividerà i 5 metodi più comunemente utilizzati.

1. Misurare il peso, prelevando il campione, utilizzando una bilancia elettronica o una bilancia analitica, con una precisione di 0,01 grammi. È più facile identificare la gomma al fluoro perché il peso della gomma al fluoro è il maggiore, superiore a 1,8, e anche la proporzione di CR ECO è superiore a 1,3. Il peso specifico è ovviamente falsato. I grandi possono essere considerati questi collanti.

2. Nel metodo di combustione, una piccola quantità di prodotto deve essere prima prelevata e bruciata. La gomma fluorurata ha generalmente un effetto di combustione normale, mentre CR e CSM si spengono senza supporto di fuoco, e NR ed EPDM bruciano con fiamme relativamente grandi. Inoltre, è possibile osservare attentamente lo stato di combustione, il colore e l'odore. Ad esempio, se l'NBR/PVC viene utilizzato insieme alla colla, il fuoco schizzerà in modo casuale in presenza di una fonte di incendio e si autoestinguerà dopo aver lasciato il fuoco, mentre il fumo sarà denso e avrà un odore acre.

3. Invecchiamento ad aria calda: prelevare il campione, metterlo nella scatola di invecchiamento per un giorno e osservare il fenomeno dopo l'invecchiamento. L'invecchiamento graduale aumenta gradualmente. CR, NR e SBR diventano fragili a 150 gradi, mentre NBR EPDM è ancora elastico. L'NBR ordinario diventa fragile quando viene portato a 180 gradi; l'HNBR diventa fragile a 230 gradi, mentre la gomma al fluoro e il silicone hanno ancora una buona elasticità.

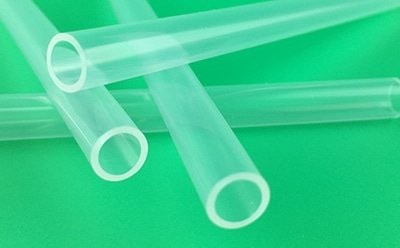

Tubi in silicone per l'industria medica

4. Resistenza all'aumento di peso medio. È possibile prelevare campioni dal prodotto finito, immergerli in uno o più mezzi selezionati, pesarli dopo una certa temperatura e un certo tempo e dedurre il tipo di materiale in base al tasso di variazione del peso e della durezza. Immersi in olio motore a 100 gradi per 24 ore, NBR, gomma al fluoro, ECO e CR presentano poche variazioni di qualità e durezza, mentre NR, EPDM e SBR hanno più che raddoppiato il loro peso e modificato notevolmente la loro durezza, con un'evidente espansione di volume.

5. Metodo a bassa temperatura: prelevare il campione e metterlo in un ambiente adatto a bassa temperatura. Immergere il campione in un ambiente a bassa temperatura per 2-5 minuti e sentire il grado di morbidezza e durezza alla temperatura selezionata. Ad esempio, a -40 gradi, rispetto alla gomma siliconica, che è anche buona in termini di resistenza alle alte temperature e agli oli, e alla gomma fluorurata, la gomma siliconica è più morbida.

Tubi in silicone per uso medico

Riassumere:

Le materie prime della gomma siliconica possono essere distinte attraverso 5 metodi, ma la situazione operativa effettiva è ancora giudicata dalla situazione in quel momento. Ad esempio, in base alla configurazione e alle condizioni esistenti nella fabbrica di prodotti in silicone, è necessario scegliere il metodo appropriato, in modo da poterlo distinguere rapidamente, risparmiando tempo e costi e garantendo l'efficienza della produzione di prodotti in gomma siliconica.

WhatsApp/Wechat: +86 13075286997

Email: sales@srtub.com