Silicone Features:

High temperature resistance: the applicable temperature range is -40 to 230 degrees Celsius, and can be used in microwave ovens and ovens.

Easy to clean: Silica gel products made of silica gel can be restored by rinsing with clean water after use, and can also be cleaned in a dishwasher.

Long service life: The chemical properties of the silicone material are very stable, and the products produced have a longer service life than other materials.

Soft and comfortable: thanks to the softness of the silicone material, the cake mold product is comfortable to the touch, extremely flexible, and does not deform.

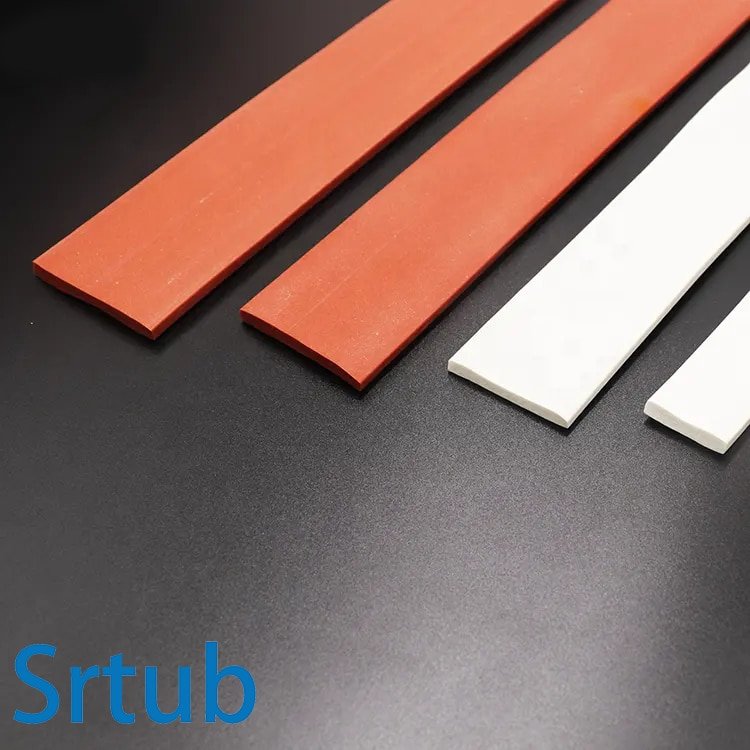

Various colors: Different beautiful colors can be prepared according to the needs of customers.

Environmentally friendly and non-toxic: No toxic or harmful substances are produced from raw materials entering the factory to finished product shipments.

Electrical insulation performance: Silicone rubber has high resistivity, and its resistance value can remain stable in a wide temperature range and frequency range. At the same time, silica gel has good resistance to high-voltage corona discharge and arc discharge, such as high-voltage insulators, high-voltage caps for TV sets, and electrical components.

Low temperature resistance: The minimum temperature critical point of ordinary rubber is -20 degrees to -30 degrees, but silicone rubber still has good elasticity at -60 degrees to -70 degrees, and some special formula silicone rubber can withstand Extremely low temperature, such as cryogenic sealing rings, etc.

Conductivity: When conductive fillers (such as carbon black) are added, silicone rubber has good conductivity, such as keyboard conductive contact points, heating element parts, antistatic parts, high-voltage cable shielding, medical physiotherapy conductive film, etc.

Weather resistance: Ordinary rubber degrades rapidly under the action of ozone generated by corona discharge, while silicone rubber is not affected by ozone, and its physical properties will only change slightly under ultraviolet light and other climatic conditions for a long time, such as outdoor use Sealing materials, etc.

Thermal conductivity: When some thermal conductive fillers are added, silicone rubber has good thermal conductivity, such as heat sinks, thermal conductive gaskets, copiers, fax machine thermal rolls, etc.

Radiation resistance: The radiation resistance of silicone rubber containing phenyl groups is greatly improved, such as electrical insulation cables, connectors for nuclear power plants, etc.

Srtub Kvalitet Hög temperaturbeständighet Skumremsa Självhäftande rulle Silikonskum Tillverkare till salu

Advantages of silicone products:

Superior performance, coupled with the fact that silica gel is a non-petroleum product and does not rely on increasingly scarce petroleum resources, makes silica gel products a substitute for similar plastic products. Such as baby pacifiers, human organs, etc., the application prospects are very broad.

Silicone use:

1. Silicone products are an indispensable part of making copiers, keyboards, electronic dictionaries, remote controls, toys, and silicone buttons.

2. It can be used as durable molded gaskets, packaging materials for electronic accessories, and maintenance materials for automotive electronic accessories.

3. It can be used to make electronic components and molded high-pressure flanges.

4. It can be used to make conductive silica gel, medical silica gel, foam silica gel, molding silica gel, etc.

5. It is used for sealing projects such as building and repairing of houses, seam sealing of high-speed kilometers, sealing of bridges, etc.

6. It can be used for baby products, mother and baby products, baby feeding bottles, and feeding bottle protective sleeves.

7. It can be used in the production of kitchen products, kitchen utensils and related auxiliary kitchen utensils.

8. It can be used for medical device accessories, and is widely used in the medical industry due to its colorless, odorless and non-toxic properties.

Srtub Kvalitet Hög temperaturbeständighet Skumremsa Självhäftande rulle Silikonskum Tillverkare till salu

WhatsApp/Wechat: +86 13075286997

E-post: sales@srtub.com